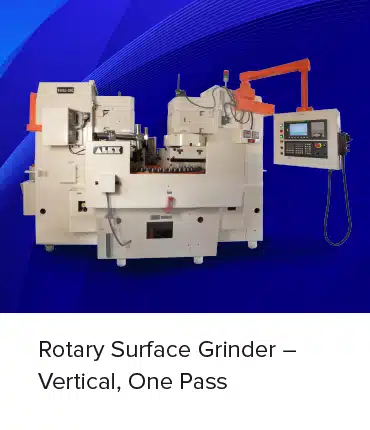

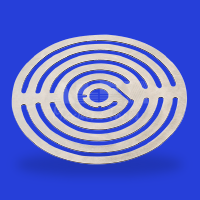

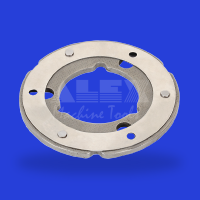

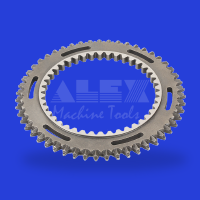

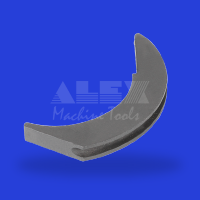

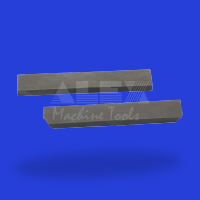

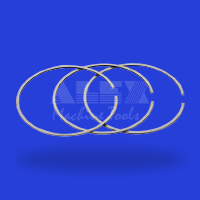

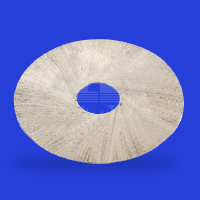

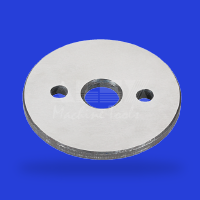

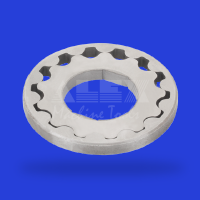

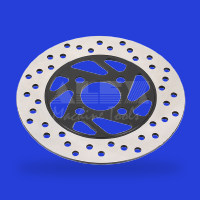

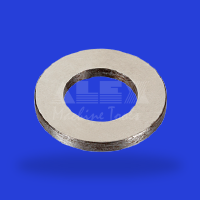

Ideal for continuous one piece flow, this Rotary Grinder is designed with a special magnetic bed that allows for loading and unloading outside the wheel and grinding in clamped condition under the wheel. Most suited for mass-scale precision grinding of thin components like washers, circlips, spacers, gears, etc. Easy to integrate with post process gaging systems for wheel wear compensation.

This configuration can also be designed to accommodate two spindles on one single piece base. This arrangement is suited where rough and finish grinding is required in a one piece flow environment.

ROTARY SURFACE GRINDER

Vertical, One Pass

Series: RA

Rotary Grinder – One Piece Flow

Our nation is at war our economy turmoil promise obligations business.

A faith in simple dream an insistence of those defining moments.

Those options are already baked in with insistence this model shoot me clear.

Those options shoot are already baked in with this model shoot me clear.

Our nation is at war our economy turmoil promise obligations business.

A faith in simple dream an insistence of those defining moments.

RA Series: Single-Pass Mastery

Adaptable to Your Needs: This series is engineered to handle a diverse array of small components with precision, catering to your specific manufacturing challenges.

Precision with Every Part: Optional post-process gauging and advanced CNC control options ensure each piece meets your exact specifications, maintaining consistency and quality.

Designed for the Shop Floor: With features focused on high-volume precision grinding, the RA Series integrates smoothly into your existing setup, enhancing both throughput and quality.

Technical Specifications – RA

MODEL | R20-A | R30-A | |

Magnet Table Diameter | mm | 550 | 550 |

Inch | 22 | 32 | |

Wheel Diameter | mm | 300 | 450 |

Inch | 12 | 18 | |

Maximum Wheel Clearance | mm | 100 | 175 |

Inch | 4 | 7 | |

Spindle Speed | rpm | 1200 | 960 (variable) |

Power Of Spindle Motor | h.p | 5 | 15 |

Table Speed | rpm | 0.5/1 | 0.5/1 |

Power Of Table Motor | hp | 1/1.5 | 25 |

Net Weight Of The Machine | Kg | 2500 | 5000 |

Lb | 5512 | 11024 | |

Power Rapid Traverse Of Motor | h.p. | 1 | 1 |

Dimension Of Machine (Length x Width x Height) | mm | 1000 x 1000 x 1650 | 2000 x 1600 x 1900 |

Inch | 40 x 40 x 65 | 79 x 63 x 75 | |

Power Of Coolant Motor | h.p | 0.25 | 0.25 |

Efficiently Integrated: The RA series is equipped with automation-ready features, allowing for effortless loading and unloading, optimizing your production flow and minimizing manual handling.

Reliable Precision: Opt for the RA series for a grinder that’s not just equipment, but a critical part of your precision manufacturing, ensuring every component meets your exact standards.

Choose an Alex Grinding Solution That Brings Unparalleled Accuracy, Reliability and Productivity to Every Workpiece

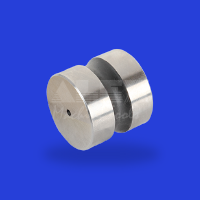

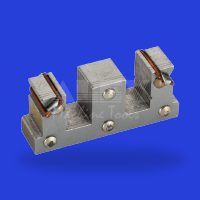

Featured Applications

Choose the Optimum Grinding

Solution for you

Solution for you

Explore our Full Line of high-precision grinding machines.

Talk to our Application Engineering Experts

Find the Optimum Grinding Solution for you now.

Phone

+91 7738781857

022 67425121 / 122 / 123

About

Products

Insights

Subscribe for Newsletter

Address

8, Gaiwadi Industrial Estate, SV Rd, Goregaon West, Mumbai: 400062.

Phone

+91 7738781857

022 67425121 / 122 / 123

About

Products

Resources

Copyright © 2026 Alex Machine Tools. All Rights Reserved. | Privacy Policy | Terms & Conditions | Disclaimer | FAQs